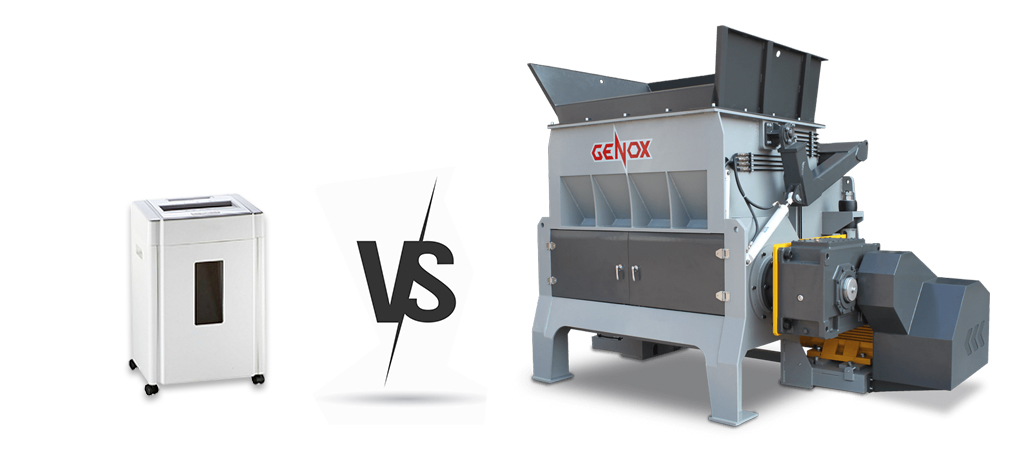

Commercial and industrial heavy-duty shredders differ significantly in several aspects. Here are the main points of these differences:

Commercial shredder:Specifically designed for commercial environment, typically used in offices, small businesses, stores, or commercial facilities. Its primary function is to dispose of daily generated paper, documents, credit cards, CDs, and other sensitive or unwanted paper materials to ensure secure destruction of information and prevent data breaches.

Industrial heavy-duty shredder:Used in large industrial settings such as recycling centers, waste disposal facilities to process large volumes of waste materials, including but not limited to paper documents. These machines typically have higher processing capacity and longer running time.

Commercial shredder:Have a relatively lower processing capacity, measured in the number of sheets processed per minute or per hour. They are suitable for small to medium-scale shredding needs.

Industrial heavy-duty shredder:Have extremely high processing capacity, able to handle large quantities of materials, reaching thousands of kilograms per hour or more. They can operate continuously to meet large-scale shredding demands.

Commercial shredder:Tend to have a more compact design, suitable for placement and use in offices or small workspace. They may have simple control panel and easily replaceable parts.

Industrial heavy-duty shredder:Has a more robust and durable design to withstand long hours of heavy-duty use. Normally it has a larger size and more complex control system to ensure high efficiency and safety.

Commercial shredder:Typically powered by standard electrical outlets and rely on electricity to drive the blades and transmission system.

Industrial heavy-duty shredder:May require more powerful power sources, some even using diesel or gas engines as power source. This design ensures continuous operation even under unstable power supplies.

Commercial shredder:Tend to have a lower price point, and maintenance and repairs are relatively simple. Users can easily purchase replacement parts and consumables.

Industrial heavy-duty shredder:Have a higher price tag, but this is justified by their powerful processing capacity and durability. Maintenance and repairs may require more specialized knowledge and skills, and spare parts may need to be replaced regularly.

Both commercial and industrial heavy-duty shredders need to adhere to safety and environmental regulations. These machines should be equipped with appropriate safety mechanisms to prevent accidents. Additionally, compliance with relevant environmental regulations and standards is absolutely essential to ensure that waste disposal does not have a negative impact on the environment.

In summary, the key differences between commercial and industrial heavy-duty shredders lie in their intended use, processing capacity, design and structure, power source, pricing, maintenance requirements, as well as safety and environmental compliance considerations. Commercial shredder is suitable for offices and small businesses with moderate shredding needs, while industrial shredder is designed for large-scale, continuous shredding in demanding industrial environments. Genox specializes in the research, development, and manufacturing of high-end equipment in the field of "solid waste resource utilization." With its globally leading technical strength and product quality for shredders, Genox is capable of providing customized services for different customer needs.

For a quote on Genox’s Shredder, Granulator, Recycling System, or help figuring out which model would be perfect for you, please contact info@genoxtech.com or click here to contact us.